List of typical equipment found in a data center

Below is the Table of Contents for the descriptive content about each main category.

The landscape of data center equipment manufacturing is dynamic and pivotal to the digital age. These companies produce a wide range of hardware essential for the operation of data centers, including servers, storage systems, network switches, and cooling solutions. Their products are designed to handle the immense computational loads and data storage needs of modern businesses, from cloud computing to big data analytics. Efficiency, scalability, and reliability are at the core of their design philosophy, with innovations focusing on reducing energy consumption and enhancing performance.These manufacturers also cater to the growing demand for high-density computing environments, offering modular and scalable solutions that can adapt to evolving technological requirements. Moreover, they play a crucial role in advancing data security, ensuring that the equipment is fortified against cyber threats. Their contributions are vital in shaping the infrastructure that supports our increasingly digital world.

Several companies manufacture data equipment, including those that offer data center hardware and those specializing in data acquisition systems. Some prominent manufacturers include Cisco, Juniper Networks, Dell, and Hewlett Packard Enterprise (HPE) for data center equipment, and Measurement Computing Corporation, Diversified Technical Systems (DTS), and NovaLynx Corporation for data acquisition systems.

Data Center Equipment Manufacturers:

- Cisco: Known for its networking hardware and solutions.

- Juniper Networks: Another leading provider of networking equipment, focusing

on advanced networking technologies. - Dell: A major manufacturer of servers, storage, and

networking solutions for data centers. - Hewlett Packard Enterprise (HPE): Offers a wide range of servers, storage, and

networking hardware for data centers. - IBM: Provides a comprehensive suite of data center hardware and

software solutions. - NetApp: Specializes in storage solutions for data centers and cloud environments.

- Netgear: Focuses on networking equipment and solutions.

Data Acquisition System Manufacturers:

- Measurement Computing Corporation: A leading provider of data acquisition systems.

- Diversified Technical Systems (DTS): Offers a wide range of data acquisition products.

- NovaLynx Corporation: Another manufacturer of data acquisition systems.

- DEWETRON: Provides data acquisition systems for various applications.

- OMEGA Engineering: Offers a variety of data acquisition tools and equipment.

- Yokogawa: Provides data loggers and other test and measurement equipment.

IQS Directory Industries

Adhesives, Ceramics & Glass

Air Handling Equipment

Air, Liquid Filters and Filtering Systems

Brushes, Brooms & Sweepers

Contract Manufacturing

Conveying Equipment

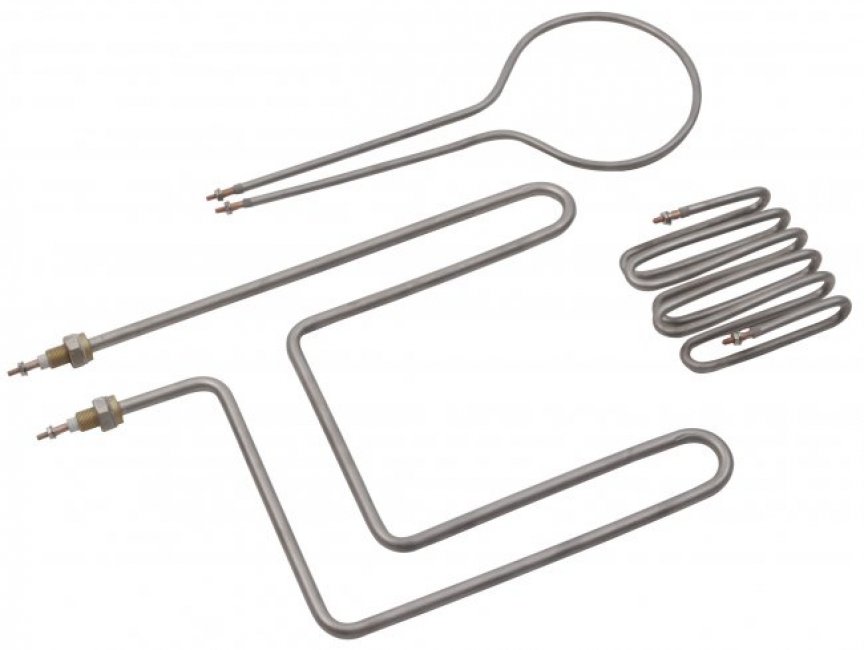

Electric Heaters

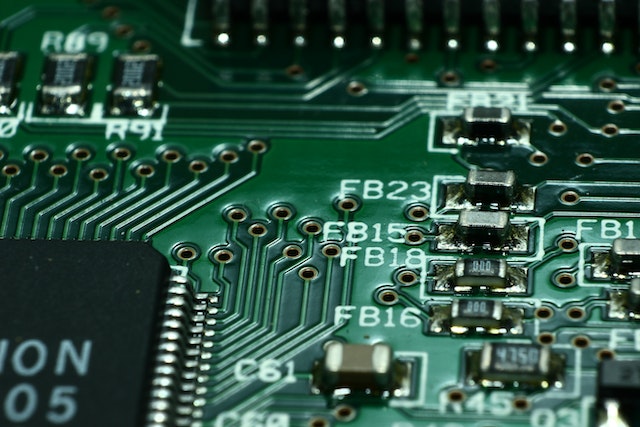

Electrical & Electronic Components

Flow Instrumentation

Hardware

Heat Transfer Equipment

Hydraulic Equipment & Supplies

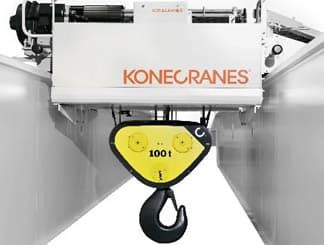

Lifting Products

Material Handling Equipment

Metal Cutting Services

Metal Forming Services

Metal Processes

Mobility Products

Motion Control Products

Plant & Facility Equipment

Plant & Facility Supplies

Power Products

Pressure Sensors & Pressure Controls

Process Equipment

Pumps & Valves

Recycling Equipment

Rubber Products & Services

Safety Equipment

Storage Products

Test and Measurement Equipment

Other Relevant Manufacturers:

- Foxconn Industrial Internet Co Ltd: A major player in communication equipment manufacturing.

- Comba Telecom Systems Holdings: Focuses on communication equipment and solutions.

- Ribbon Communications: Provides communication equipment and software solutions.

- ADVA Optical Networking: Specializes in Carrier Ethernet edge solutions.

- Communications & Power Industries (CPI): Manages electronic components for the communications market.

Here is a list of typical equipment you might find in a data center:

- Servers:

- Rack servers

- Blade servers

- Tower servers

- Storage Systems:

- Network Attached Storage (NAS)

- Storage Area Network (SAN)

- Direct Attached Storage (DAS)

- Networking Equipment:

- Routers

- Switches (Layer 2 and Layer 3)

- Load Balancers

- Firewalls

- Network Interface Cards (NICs)

- Power Management:

- Uninterruptible Power Supplies (UPS)

- Power Distribution Units (PDUs)

- Generators for backup power

- Cooling Systems:

- Computer Room Air Conditioners (CRAC)

- Computer Room Air Handlers (CRAH)

- In-row cooling units

- Liquid cooling solutions

- Racks and Enclosures:

- Server racks

- Cabinets

- Open frames

- Cabling and Infrastructure:

- Fiber optic cables

- Copper cables (Cat5, Cat6, etc.)

- Cable management systems

- Patch panels

- Security Systems:

- Surveillance cameras

- Biometric access controls

- Key card systems

- Clean Rooms

- Environmental Monitoring:

- Temperature sensors

- Humidity sensors

- Smoke detectors

- Facility Management:

- Raised floor systems for air circulation

- Fire suppression systems (like FM-200, inert gas systems)

- KVM Switches (Keyboard, Video, Mouse) for remote management of servers.

- Management and Monitoring Tools:

- Data center infrastructure management (DCIM) software

- Remote management cards/IPMI (Intelligent Platform Management Interface)

- Materials Used In Data Centers

This list covers the essentials but remember, the exact equipment can vary based on the scale, purpose, and technology standards of each data center.

What is the Outlook for Data Equipment Manufacturers?

Answer: The outlook for data equipment manufacturers in 2025 is cautiously optimistic, driven by technological advancements, rising demand, and a focus on sustainability, though tempered by economic and geopolitical challenges. Drawing on industry trends and insights from sources like Deloitte, Infosys, and JLL, here’s a concise overview.

Growth Drivers: The semiconductor industry, a key supplier for data equipment, is projected to reach $697 billion in 2025, an 11% increase year-over-year, fueled by demand for AI, data centers, and 5G technologies (Infosys). Data centers, critical for data equipment, are expanding rapidly, with 10 GW of hyperscale and colocation projects breaking ground globally, equating to $170 billion in asset value (JLL). AI-driven systems, such as predictive maintenance for data center equipment, are becoming essential, boosting demand for advanced hardware (AlphaSense). Additionally, investments in clean-technology manufacturing, totaling $31 billion in 2024, are creating nearly 27,000 jobs, supporting long-term growth (Deloitte).

Challenges: Economic uncertainty looms, with potential policy shifts post-2024 U.S. elections impacting supply chains and costs (Deloitte). Geopolitical tensions and trade barriers may force manufacturers to diversify supply chains, as tech firms face cybersecurity and quantum computing risks (Deloitte Tech Outlook). Rising raw material costs and a global IT skills shortage, projected to cause $5.5 trillion in losses by 2026, add pressure (TechTarget). Data equipment for edge computing, while in demand, faces hurdles like power availability and security in decentralized setups (AlphaSense).

Sustainability Focus: Manufacturers are prioritizing energy efficiency, with data centers adopting liquid cooling and renewable energy to meet regulatory and investor demands (AlphaSense). This aligns with broader industrial trends toward electrification and decarbonization (Deloitte).

Critical Perspective: While industry reports are bullish, they often overlook potential over-optimism in AI and data center growth projections. Economic slowdowns, hinted at by Deloitte’s labor market concerns, could dampen demand more than expected. Additionally, the push for sustainability might strain manufacturers if infrastructure investments lag.

Conclusion: Data equipment manufacturers can expect growth in 2025, particularly in AI and data center sectors, but must navigate economic volatility, supply chain risks, and sustainability pressures. Strategic investments in innovation and workforce skills will be key to staying competitive.

A Brief History of Data Equipment Manufacturers

The history of data equipment manufacturers traces back to the early 20th century, when the need for efficient data processing emerged alongside growing businesses. Early pioneers like IBM, founded in 1911 as the Computing-Tabulating-Recording Company, revolutionized data handling with punch-card machines. These devices, used for census tabulation and business accounting, laid the groundwork for automated data processing, marking the birth of the data equipment industry.

World War II accelerated innovation, as governments demanded faster computation for cryptography and logistics. This era saw the rise of early computers, with companies like IBM developing the Harvard Mark I in 1944. Post-war, the 1950s brought magnetic tape storage and the first commercial computers, such as the UNIVAC I by Remington Rand, which transformed business data management.

The 1960s and 1970s marked the mainframe era, dominated by IBM’s System/360, a versatile family of computers that standardized data processing. During this time, other players like Hewlett-Packard (HP) emerged, focusing on specialized equipment like minicomputers. The 1980s introduced personal computers, with manufacturers like Dell and Compaq making data equipment accessible to smaller businesses, while Cisco pioneered networking hardware, enabling data connectivity.

The internet boom of the 1990s shifted focus to servers and storage, with companies like EMC (now Dell EMC) leading in data storage solutions. Today, manufacturers like Lenovo, HPE, and Dell dominate, producing advanced servers, cloud infrastructure, and AI-driven equipment, reflecting the industry’s evolution from punch cards to global data ecosystems.

How to Find the Right Data Equipment Manufacturer Using IQSdirectory.com

Selecting the right data equipment manufacturer is crucial for businesses needing reliable solutions like data acquisition systems, loggers, or software for industrial applications. IQSdirectory.com, a comprehensive online resource, simplifies this process by connecting buyers with trusted manufacturers across the U.S. and Canada. Here’s a step-by-step guide to finding the perfect data equipment manufacturer using this platform.

First, visit IQSdirectory.com and use the search bar at the top of the page. Enter specific keywords like “data acquisition systems” or “data loggers” to narrow your focus. The site organizes results by industry and product categories, ranging from broad (e.g., test and measurement equipment) to specific (e.g., DAQ suppliers), ensuring you find relevant manufacturers quickly.

Next, browse the search results, which display premium manufacturers with website previews, often sorted by state for geographic relevance. Hover over a company name to see a snapshot of their profile, including contact details and product offerings. For deeper insights, click “View Company Profile” to explore their capabilities, certifications, and customer reviews. This helps you assess if a manufacturer aligns with your technical needs, such as integration with existing systems or specific software support.

Once you’ve shortlisted potential manufacturers, use the “Request a Quote” feature to submit inquiries directly. This tool streamlines communication, requiring only essential contact details to initiate a response, saving you time. Additionally, check the IQS Newsroom for industry updates, which can highlight manufacturers involved in innovative data equipment solutions.

By leveraging IQSdirectory.com’s targeted search, detailed profiles, and direct contact options, you can efficiently find a data equipment manufacturer that meets your industrial requirements with precision and ease.