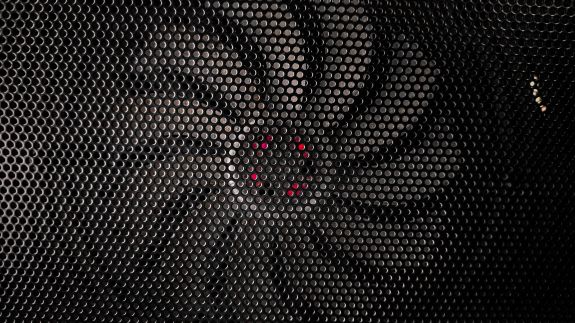

Electronic enclosures require adequate ventilation, air circulation, protection, and stability to ensure the proper performance of the components, circuits, and equipment contained in an enclosure. Electromagnetic inference (EMI) and radio frequency interference (RFI) are two factors that inhibit the function of electronic components and must be dissipated by the walls of electronic enclosures.

In data centers, where servers, computers, and other electronic devices are stored, perforated metal sheets are used for the construction of the doors and walls of electronic instrument enclosures. Made of precision crafted and highly durable materials, perforated metal sheets are used to construct electronic enclosures due to the high strength and stability of perforated metal sheets. Designed with openings that allow for even air flow, perforated metal sheets offer the protection that is required by electronic equipment with openings that permit consistent air flow to maintain even temperatures.

When perforated manufacturers engineer and design perforated metals for electronic enclosures, there are certain factors that are essential to their planning, which include the size of the perforated openings, air flow, the strength of the metals, and the possible need for impact protection. Even though perforated metal sheets have holes to allow light and air through, they retain the strength of the metals from which they are made, a factor that necessitates careful selection of the metals used to manufacture electronic enclosures.

Ventilation

Although perforated metal sheets have a pleasing aesthetic appearance, their main function in many applications is to ensure the proper flow of air throughout an environment. This is accomplished by the proper positioning of the holes in the sheets such that air passing through the sheets is directed in way that preserves the temperature and air quality such that it is uniform in all parts of an open space.

The air flow factor of perforated metal sheets is critical to the smooth operation of data centers, which have HVAC systems that are designed to maintain a stable environment.

In data centers, perforated metal sheets retain their function as a method for directing air flow and air streams to ensure that every part of a server room and data center has a consistent temperature level and clean air.

The endurance and flexibility of perforated metal sheets adds a second responsibility to their construction, which is the protection and preservation of electronic components. The openings punched into perforated metal sheets that form the doors and walls of electronic enclosures are designed to direct the air flow into the enclosure to dissipate the heat generated by the many electronic circuits. Perforated metal sheet engineers and electronics experts work together to design the most efficient ventilation system for the ducting system of data centers and the sheets that make up the doors and walls of the enclosures. The planning of these experts ensures the even distribution of air and the maintenance of a uniform temperature level.

Strength

A key factor regarding perforated metal sheets for electronic enclosures is strength, which is necessary for the protection of electronic circuits, devices, wiring, and equipment. Although it is highly unlikely that any form of impact will damage the electronics of a data center, there are other threats that can disrupt the function of equipment, such as EMI and RFI interference.

EMI and RFI are unwanted interference in an electrical circuit that is caused by an outside source. They occur due to the close relationship between electricity and magnetism that comes with electrical current. In data centers, the close proximity of different forms of electronics can emit interference that causes electronics to perform poorly, malfunction, or stop working. In many cases, various forms of shields are used to protection.

Perforated metal sheets that are used to manufacture electronic enclosures provide protection from EMI and RFI interference due to the non-conductive metals that are used in their construction. Although perforated metal sheets are not solid pieces of metal, they have a sufficient amount of surface to block and inhibit stray electronic signals. This aspect of their function helps maintain the integrity of a data center and protect it from the harm stray electronic signals can cause.

Stability

Perforated metal sheets used for the assembly of electronic enclosures are highly durable and strong. This aspect of perforated metal sheets is a necessity for protection as well as the longevity of electronic enclosures. Unlike most manufacturing processes and operations, data centers are constantly in use, every hour of the day, which places a strain on equipment and electronic circuits. It is essential that every part of a data center be dependable and consistent to meet the demand.

The high quality of the engineering and ingenuity that goes into the manufacture and design of perforated metal sheets ensures their lasting power. Each aspect of the production process is carefully monitored to guarantee quality and endurance. Perforated metal sheet manufacturers take pride in the performance of their products and work diligently to ensure high quality and dependable performance.

Customization

Perforated metal sheets are normally manufactured using a common set of perforated patterns that are generally accepted for a wide range of applications. The special nature of data centers requires the use of specially chosen materials that meet the standards and demands of data centers and their technical equipment. The adaptability and flexibility of perforated metal sheets make it possible to custom design sheets that specifically meet the unique requirements of every data center. The close collaboration between perforated metal sheet manufacturers and data center management ensures custom fit perforated metal sheets.

Information provide by Accurate Perforating.

Leading Perforated Sheet Metal Manufacturers

Accurate Perforating Company, Inc. open_in_new

Location: Chicago, IL

Accurate Perforating is a one-stop shop for complete perforated metal solutions. We can perforate, fabricate and finish almost any metal for almost any use. Whether you need perforated aluminum, carbon steel, galvanized, stainless steel, or copper; in perforated sheets, coils, parts or finished components; or architectural metal, decorative metal, railings, facades or sunscreens — with the widest range of thickness, hole size or pattern — we’re the perforated sheet manufacturer you can trust.

Ametco Manufacturing Corporation open_in_new

Location: Willoughby, OH

At Ametco Manufacturing Corporation, we specialize in custom manufacturing a wide range of quality products, including perforated metals, and plastics. Our expertise extends to crafting, perforated sheet, perforated tubes, and perforated metal filter screens. As specialists in metal perforation, we adhere to the strictest guidelines to ensure that every product we deliver meets the highest standards of quality.

Remaly Manufacturing Company, Inc. open_in_new

Location: Tamaqua, PA

Here at Remaly Manufacturing Company, Inc. we aim to exceed your expectations. Our teams utilize the most efficient manufacturing processes and we strive to provide you with the highest quality solutions. All of our products are pre-tested and we work with you to determine the best perforated metals for your applications.

VACCO Industries, Inc. open_in_new

Location: South El Monte, CA

Here at VACCO Industries, we can create custom perforated metal products, and our engineers will abide to your exact requests. These top of the line products are affordable, and we work hard to make all of our products with precision techniques. We take pride in saying that we are the largest commercial photo etching company in the Western United States. We are the experts of a plethora of metals and secondary services such adhesive and diffusion bonding.