Machine vision technology is increasingly integrated into data centers to enhance automation, improve efficiency, and ensure operational integrity. Here are the key ways machine vision is used in data centers:

Asset Management and Inventory:

- Automatic Inventory Tracking:

Machine vision systems can scan and record serial numbers, barcodes, or QR codes on servers, storage units, and networking equipment, aiding in real-time inventory management. This reduces manual labor for asset tracking and ensures accurate records.

- Rack and Equipment Positioning:

Vision systems can help in mapping out equipment locations within racks, ensuring that assets are placed correctly according to optimal cooling, power distribution, and network topology.

Maintenance and Monitoring:

- Predictive Maintenance:

By using cameras to monitor equipment for signs of wear, overheating, or unusual behavior (like smoke or unusual light from LEDs), machine vision can help predict maintenance needs before failures occur, thus reducing downtime.

- Health Monitoring:

Visual inspection can detect physical irregularities or damage to cables, connectors, or hardware, prompting timely intervention.

Security:

- Surveillance: Machine vision enhances security through advanced video surveillance systems capable of recognizing unauthorized access, unusual behavior, or intrusions. Facial recognition or object detection can be part of this.

- Access Control: It can be used to verify identity at entry points or for accessing specific areas, improving security measures beyond traditional key or card systems.

Compliance and Auditing:

- Audit Trails: Machine vision can assist in creating visual logs of hardware configurations or changes, which are crucial for audits, compliance with standards, or during incident investigations.

- Regulatory Compliance: For data centers in regulated industries, machine vision can ensure that physical security or operational practices meet specific standards.

Operational Efficiency:

- Cable Management: By employing vision systems to analyze cable layouts, data centers can optimize cable management, ensuring efficient airflow, reducing clutter, and minimizing errors during maintenance.

- Energy Efficiency: Vision systems can monitor power usage effectiveness (PUE) by analyzing the operational state of equipment, identifying units that might be running inefficiently or unnecessarily.

Quality Control and Assembly:

- Installation Verification: During server or equipment installation, machine vision can verify that components are correctly placed, wired, and configured according to specifications.

- Quality Checks: Automated visual inspections can ensure that new installations or upgrades meet quality standards before they go live.

Data Center Construction and Renovation:

- Progress Monitoring: Vision systems can track the progress of construction or renovation projects by analyzing images or video feeds, ensuring that milestones are met and detecting deviations from plans.

Environmental Monitoring:

- Dust and Debris Detection: In clean room environments or during maintenance, machine vision can identify dust or debris that could compromise equipment reliability.

Remote Management:

- Remote Inspections: With the ability to analyze images or live feeds, remote management of data centers becomes more feasible, allowing for oversight of operations from anywhere in the world.

Use in Edge Computing:

- Edge Vision Applications: At edge data centers, where space and resources are more limited, machine vision can be used for local processing of visual data, reducing latency for applications like security or automated monitoring.

Machine vision in data centers leverages the precision, speed, and accuracy of visual data processing to automate tasks, enhance security, improve maintenance practices, and ensure operational efficiency, thereby contributing significantly to the modern data center’s operational paradigm.

Leading Machine Vision Manufacturers

Cincinnati Automation Ltd. open_in_new

Location: Florence, KY

When it comes to machine vision systems, we have the tools to get the job done right. We work hard to provide the best solutions and products to meet our customers’ demand. It is our goal to work with you from start to finish on all aspects of design and production. We will do our best to provide the solution to even your most challenging requirements. Find out more by contacting us today!

Cognex Corporation open_in_new

Location: Natick, MA

Our machine vision systems are used around the world in millions of applications. We believe in creating products that work, and our customers trust us to create innovative and effective designs they can rely on. You will find that we face even the most difficult challenges with ease. Contact us today to learn more about how we can help you!

Six Sigma Concepts, LLC open_in_new

Location: East Longmeadow, MA

At Six Sigma Concepts, LLC, we specialize in designing and integrating advanced machine vision systems that bring precision, consistency, and intelligence to modern manufacturing. We combine engineering expertise with cutting-edge imaging technologies to deliver custom vision solutions that automate inspection, measurement, and process control with remarkable accuracy.

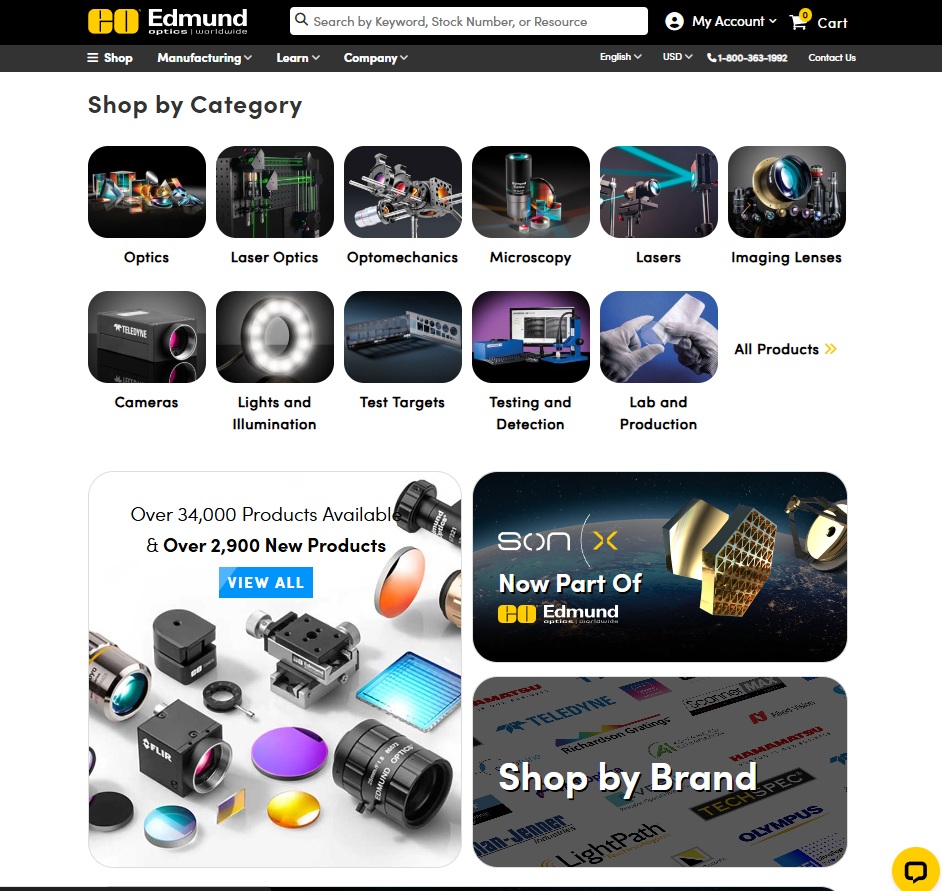

Edmund Optics open_in_new

Location: Barrington, NJ

Edmund Optics is a leading optical manufacturer, offering world-class components, assemblies, and services. We can design custom lenses, optical prisms, beamsplitters, optical filters, windows, and laser optics, while offering a range of single/multi-layer coating options.